Engineering, Manufacturing & Industrial Services.

Helping innovators have the greatest impact.

-

Product Development

We can bring your consumer product, industrial equipment, medical device, or other concept concept to market through our proven design-for-manufacture (DFM) and development process. Fitz-Thors works with companies, start-ups, and innovators of all sizes to turn ideas into prototypes for a successful and scalable manufacturing business strategy.

-

Medical Devices

Fitz-Thors is a developer and contract manufacturer of medical products and components for the medical and life sciences industries. We operate an FDA Registered Facility with ISO 13485:2016 certification. We offer in-house design, engineering, prototyping, and contract manufacturing for precision medical instruments, devices, or equipment.

-

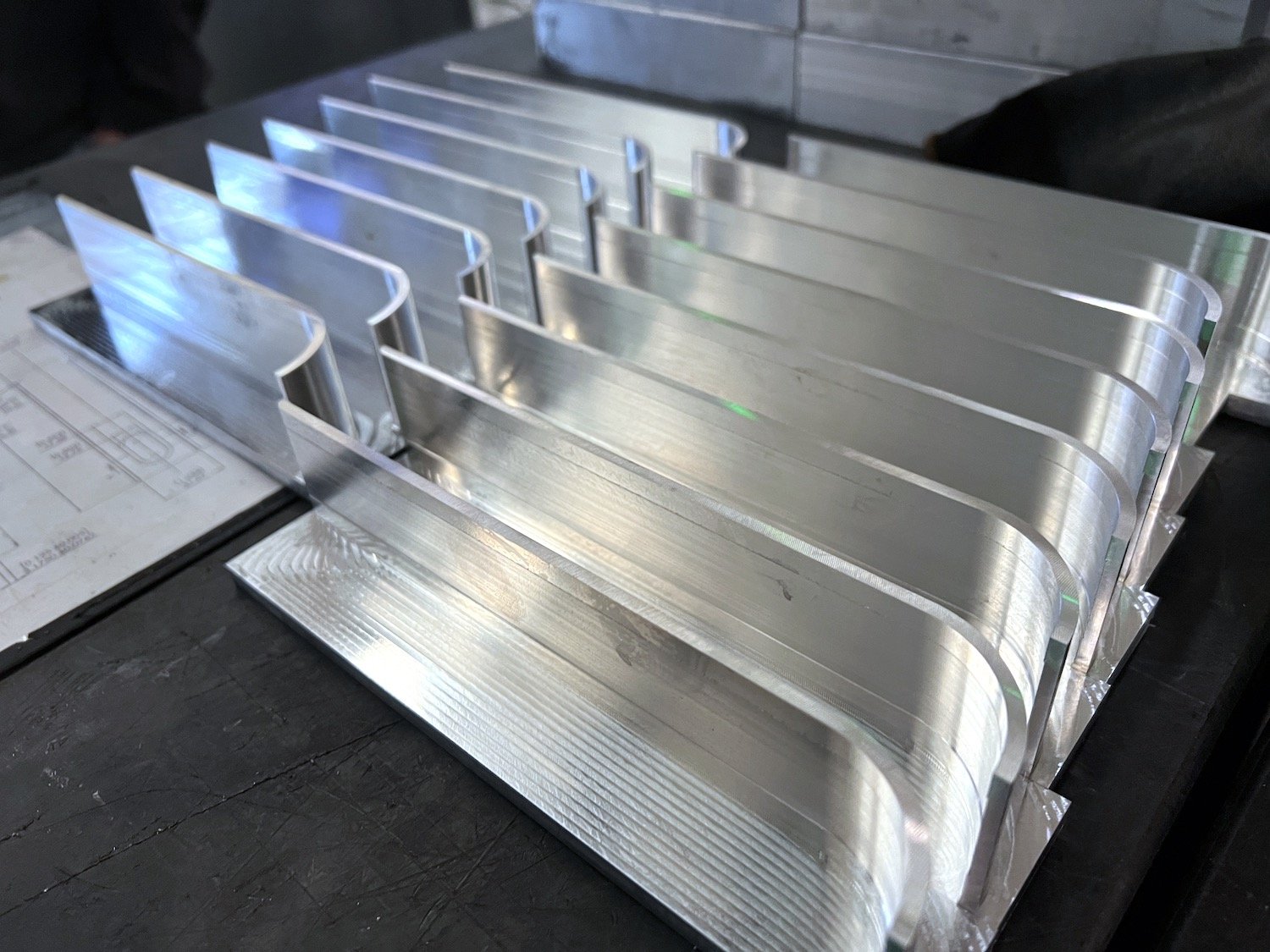

Contract Manufacturing

Fitz-Thors Manufacturing is U.S. based and ISO 13485:2016 certified, offering comprehensive prototyping and production run services for companies developing consumer products, medical devices, parts, or components. We support Fitz-Thors Engineering projects while working with a range of business types to provide contract manufacturing solutions.

-

Industrial Solutions

Fitz-Thors is a licensed industrial contractor supporting the manufacturing sector through process engineering and technical expertise. We work with some of the largest manufacturers in the U.S. to help minimize downtime and improve process efficiency and safety in factories and plants. Our team is ready to machine custom parts and tools, provide assembly services, or perform onsite work.

Fitz-Thors supports manufacturers and innovators by providing world-class engineering design, product development, prototyping, contract manufacturing, and industrial services.

Learn about the Fitz-Thors family of companies, including Fitz-Thors Engineering and Fitz-Thors Manufacturing.

Services and Capabilities

Product Development

Professional Engineering Services

Certified for Medical Devices

Mechanical Engineering

3D Modeling

CAD / CAM

Analysis / Test Inspection

Research and Development

Design Packages

Design for Manufacturing

Product Design

Prototyping Services

Manufacturing Services

Connected Devices / IoT

Sensors

Production Runs

ISO 13485 Certified Manufacturing for Medical Devices

CNC Milling, Machining, and Lathe

Fabrication

Cutting Services

3D / Additive Printing

Prototyping

Assembly

Industrial Contracting

Licensed for Onsite Equipment and Facility Work

Custom Tooling and Machines

Process Evaluation

Engineering Services

Machine Installation

Part / Tool Design and installation

Equipment Assembly

MayTec Aluminum Profile Distributor

DEMAG Crane and Components Distributor

Industries Served

Fitz-Thors is proud to work with businesses of all sizes across a wide range of industries, including many recognizable companies and brands.

Automotive • Textiles • Steel Manufacturing • Construction • Chemicals • Polymers • Electronics • Appliances • Aerospace & Defense • Research and Development • Consumer Products • Medical Devices and Products